Turning waste into clean energy isn’t just an innovation…

It's a revolution

Clean6 is a British company which has developed ground-breaking technology to generate heat energy for de-centralised power.

Based in Yorkshire, Clean6 is founded on the tradition of great British engineering.

Our ambition is simple: to educate industry and develop energy generating solutions which are more affordable, more environmentally friendly and more efficient.

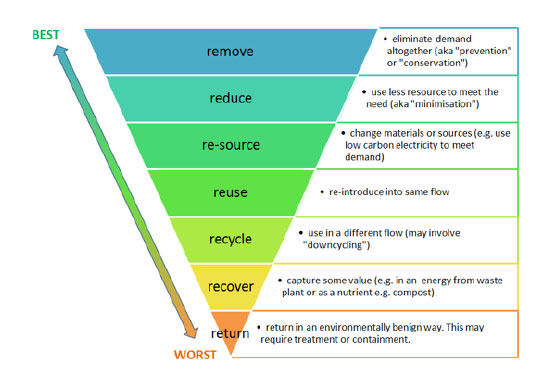

End of life material should be put alongside the waste hierarchy to see if any or all the constituents can be recovered or re-used. Assuming this has been done correctly there are two options – Landfill the material or Incineration of one sort or another. Landfill produces greenhouse gasses such as Methane (now captured for power production) and liquids such as leachate which require constant monitoring and disposal.

Incineration (in its many forms) converts waste into heat but the byproducts of Ash, Fly Ash, Dioxins, toxins and further disposal/clean up do not make the process very friendly.

Both solutions require considerable space for various tasks including clean up, gas cleaning, treatment and storage for ash prior to onward disposal.

Because of the high rotational air speed and optimal operating temperature, the Vortex can cope with fuels that other systems would struggle to process due either to contamination or low particle size. The Vortex completely destroys organic based fuel, providing it has a maximum moisture content of 20% and a maximum particle size of 3mm.

The Vortex could provide, for instance, a remote refugee camp with a source of self-sufficient energy that can be installed and removed without fuss. It could provide an inner-city hospital with a cost-cutting solution to cheaper power/heat and cost efficient disposal.

Sawdust or

contaminated MDF Dust

PU dust

Dehydrated poultry litter or silage

Dried food

waste

Coal dust

Recycling industry residues, refuse derived fuels, and plastics

Materials no longer allowed in landfill

Companies that produce a lot of waste, whether it is agricultural, industrial, or potentially hazardous. Even fly ash, which can cost £130/tonne to dispose of in landfill, can be turned into vitrified residue.

For smaller companies, the Clean6 Vortex requires minimal installation, is self-contained, and can run 24/7, or according to need.

Any business, small or large-scale, that wants a renewable source of cheap, clean energy. The Clean6 Vortex can supply anything from 125 KWe to 910KWe per system and it’s scalable for larger enterprises.

If you can find it, let us know. Set up costs for this “off-the-shelf” unit are minimal and maintenance is available.

The Clean6 Vortex is compliant with current emission limits and is CE marked. Waste residues can have further uses (depending on type), becoming a commodity not a cost.